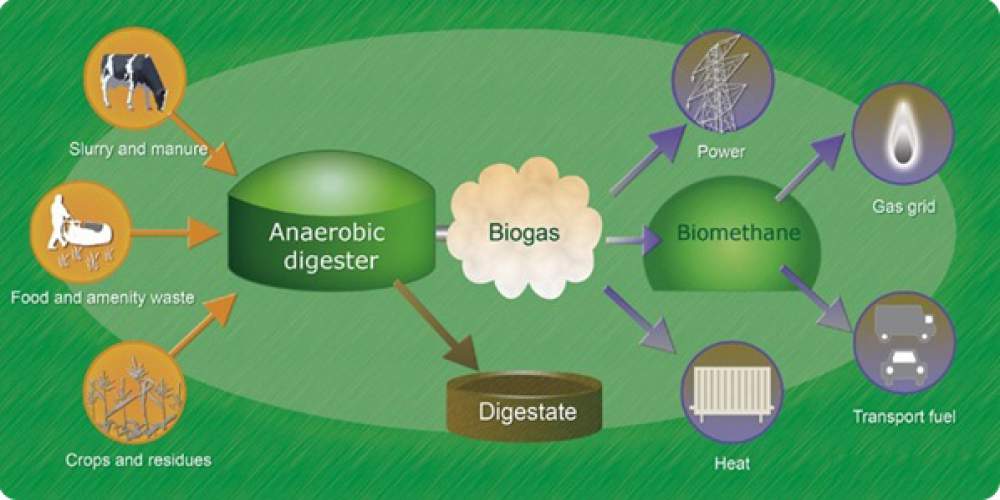

Anaerobic Digesters

Anaerobic Digesters use microorganisms to breakdown biological material which, as their by-product, produce methane gas. This process takes place in the absence of oxygen and is most popularly seen in the fermentation process that is found in beer and lager production. It has also been used for quite a while in developing countries, on small farms and in buildings, providing power for cooking and lighting.

Anaerobic digesters are beginning to be used more in the UK as a way of creating renewable energy and dealing with the problem of our daily waste. For green technology it presents a win-win situation that can be carried out on an industrial scale.

History of Anaerobic Digesters

Anaerobic digestion is another green technology that actually goes back some time. In the 10th Century BC, it was reputedly used to heat water in Assyria and the Persians were fond of doing the same thing right up until the 16th Century. The first scientist to realise that anaerobic digesters could be used for producing flammable gasses was Flemish chemist Jan Baptist van Helmont in the 17th Century.

It wasn’t long before the first anaerobic digester factory was in operation in the mid-1800s in India. In most recent times, the country with the best record of working with the technology is Denmark who, by 2000, had introduced an energy production initiative that saw biogas levels doubled.

In 1895 in England, the first gas was produced by a septic tank on farmland to provide gas lighting and the first patented technology specifically for producing gas was registered in Germany for the Imhoff Tank. The UK has generally been quite a way behind their European counterparts when it comes to anaerobic digestion but that is beginning to change as councils and businesses across the country embrace the new technology.

How Anaerobic Digesters Work

Anaerobic digesters are simple in concept. All you need is an air (oxygen) tight container, some waste and some microbes. The microbes break down the waste and produce biogas along with a nutrient rich liquid, or fertilizer. The methane gas can then be fed into a combined heat and power unit that can be used to produce electricity which, in turn, is used to power a home or exported to the national grid.

A large amount of waste is needed to produce biogas which is why it is not currently suitable for domestic use but is ideal for medium to large size applications that can often serve whole communities.

Types of Anaerobic Digesters

There are a wide variety of anaerobic digesters that can produce methane gas and they are beginning be used on an industrial scale in the UK. There are two main systems, dependent on temperatue: Mesophilic where the digester operates at 25 and 45 degrees centigrade and Thermophilic that works at higher temperatures. Thermophilic is generally a quicker process but is a more expensive technology. Anaerobic digester processes can also be wet (where water is added) or dry and either work in continuous flows or in batches.

Benefits of Anaerobic Digesters

Anaerobic digesters have a wide range of benefits environmentally, economically and for agriculture. The process produces a renewable source of energy replacing fossil fuels and it does it from waste, cutting down costs. It can, under the right circumstances, produce electricity and heat that can be used to power a farm house, factory buildings or, with large scale plants, provide valuable energy for urban areas.

Anaerobic digesters also produce valuable liquid fertilizer as a by-product that can be used in agriculture. Anaerobic digestion has been touted as the perfect solution and a sustainable way to deal with all the organic waste that we produce by the millions of tonnes every day. Most food waste no longer goes to land fill sites as it did in the past, it goes to anaerobic digesters.

Domestic Anaerobic Digesters

The possibility for domestic anaerobic digesters is extremely close at the moment, with final phase of design and development fully underway. The hope is that the average household will produce enough waste to make it a viable addition to the growing list of renewable technologies that are benefiting homes.

According to current research it takes around a tonne of waste to produce 140 cubic metres of biogas. There is also the fact that the UK is generally too cool for Mesophilic anaerobic digestion to produce the required quantity of biogas (the optimum temperature is 35) it may be possible to increase the ambient temperature to help achieve the optimum state. The only current way forward for homes is to take part in communal projects to collect their waste for larger scale anaerobic digesters that can feed the community with renewable energy as is now happening with most councils across the country.

Technology is advancing more quickly now that we are embracing the green agenda and it may be the case that more efficient or hybrid applications will developed in the future which means that individual households will be able to produce their own biogas from their waste.

Commercial Anaerobic Digesters

Many local councils in the UK are now utilising the potential of generating substantial quantities of biogas from our collective waste materials. Farmers have been doing it for a while, benefitting also from the production of valuable fertilizer for their fields. Small size anaerobic digesters can be installed for farms, commercial concerns and communities and the hurdle of getting planning permission has been relaxed in the last few years to encourage development in this area.

In July this year, Sainsbury announced that its Cannock store was going to be the first supermarket to be powered by anaerobic digestion from food waste. The company is the biggest user of anaerobic digestion having made a decision some time ago not to send any of its food waste to landfill but have it recycled instead.

Large Scale Anaerobic Digesters

There’s no doubt that anaerobic digestion works more effectively at the moment when it is planned on a grand scale. In March this year the UK’s largest anaerobic digestion plant came on line on a farm in Redford, Nottinghamshire. It is a 3 MW facility that is capable of providing electricity for more than 6,000 homes.

The brewery industry is also embracing the idea of anaerobic digesters for dealing with their waste products. Brewers Adnams have even created a new arm to their business that deals specifically in producing biogas from brewing and food waste.

Councils have been amongst the forerunners of building industrial anaerobic digestion plants to deal with the large amount of food waste that local communities produce, such as the Walpole Plant in Somerset, which processes 30,000 tonnes a year and can provide power for 1,700 homes in a year.

Funding for Anaerobic Digesters

Whilst there is no funding for domestic premises, and no real need, for anaerobic digesters, small and larger scale operations, such as those often found on farms, can benefit from the government’s Feed in Tariff if the process is used to create electricity, or from the Renewable Heat Incentive that rewards you for producing biogas. Initiatives are beginning to be brought forward such as the Rural Community Renewable Energy Fund that is run by the government bodies Defra and the DECC.

It’s a case of watch this space to see if more initiatives start coming through in the next few years as far as anaerobic digestion is concerned.

Are Anaerobic Digesters Worth It?

There is no doubt that, on a large enough scale, anaerobic digesters provide a valuable source of renewable energy and a good return on investment. The problem they will always face is in collecting enough waste product to produce the biogas that can be used to feed homes with heat and power. For the moment the emphasis is on industrial, local community and farm anaerobic digesters that have the waste and capacity to produce a significant amount of biogas.

The Future of Anaerobic Digesters

According to research, there are around 4,000 large scale industrial plants in Europe but only 25 of those are currently in the UK. The growth of communal anaerobic digesters has grown more out of a desire to do something about the amount of food waste we produce on a massive scale rather than a fervent desire to produce a renewable energy along with a little fertilizer.

From farms to food manufacturers, there is a growing interest in finding solutions to our problem of waste. In 2014 the Scottish government banned any food waste from being sent to landfill and there are suggestions that similar bans should be introduced for the rest of the UK.

One of the problems for very large scale anaerobic digesters is getting rid of the digestate – the solid mass that is left after the process is completed. Some research has found that putting too much into the land can cause an over surplus of nutrients that can actually be harmful to animal and plant life. A number of energy experts have said that, to address this problem, the future of anaerobic digesters is in small to medium scale plants that produce 500 to 2,000 kW of biogas energy and less solid by-product.

So what about the future of domestic anaerobic digesters? Whilst the problem will always be in getting enough waste product to generate enough biogas to make the investment worthwhile, it may be in the future that we will be using hybrid technology that combines several renewable approaches, linking them together in the same device. That, however, is a long way off into the future.

Installers and Manufacturers of Anaerobic Digesters

There are a number of specialist installers and manufacturers of small, medium and large scale anaerobic digesters. An installation of medium size anaerobic digester can take up to six months and will obviously require planning permission.

There’s no doubt that the development of new technologies for anaerobic digestion is one of the most exciting things for renewable energy creation and tackling that all important problem of dealing with our ever growing waste. If this technology interests you or you own a farm or other suitable business then contact us and we can have someone help discuss your options free of charge and with no obligation.